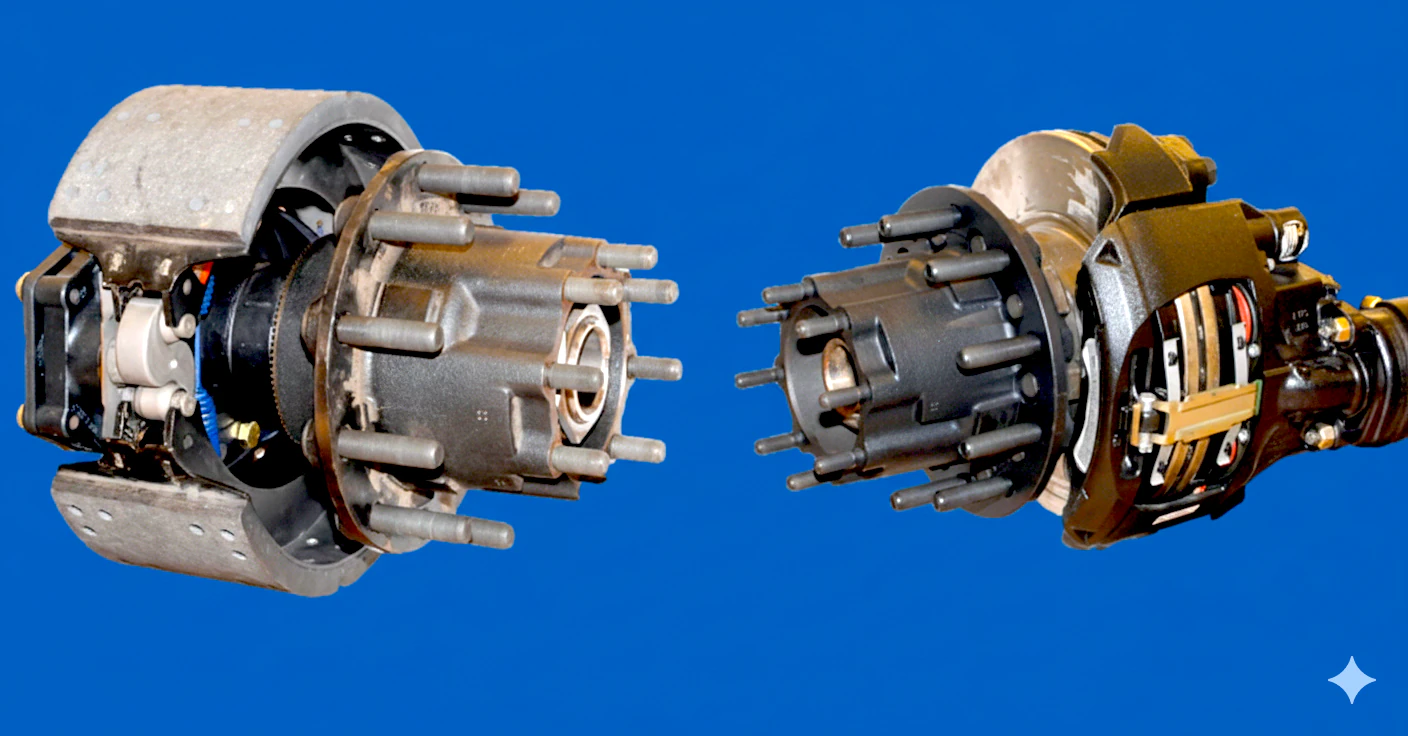

It may seem delayed, but it’s strategic. Discover how drum brakes save millions for fleet operators and outperform discs in durability.

Have you noticed that while your passenger car probably uses modern disc brakes on all four wheels, the road giants—trucks worth hundreds of thousands of dollars and carrying valuable loads—still mainly rely on drum brakes, a technology over a century old? The answer isn’t indifference or technological lag. On the contrary, it’s a brutally pragmatic decision involving money, physics, and the harsh conditions of the roads, especially here in the USA.

Cost Factor is King: The Bottom Line for Fleet Operations

In the world of road transportation, every cent counts. Fleet operators and independent truck drivers operate with tight margins, and the Total Cost of Ownership (TCO) of a vehicle is a sacred metric. This is where drum brakes shine.

- Manufacturing and Parts Cost: Drum systems are significantly cheaper to produce, install, and replace. The shoes and drums cost less than the high-performance discs and pads required for a 40-ton vehicle.

- Simplified Maintenance: The mechanics of a drum brake are widely known by technicians across the USA. This means repairs can be quickly done at almost any roadside workshop, reducing truck downtime. Reducing downtime is crucial, as well as identifying other issues that can immobilize a vehicle, such as signs that the spark plug is failing.

- Availability: Finding replacement parts for drum brakes is easy and fast, which isn’t always the case with more specialized disc systems for heavy vehicles.

For a company managing dozens or hundreds of trucks running thousands of kilometers per month, the savings generated by the simplicity and robustness of drum brakes are enormous.

Durability and Performance: Built to Handle Severe Braking Loads

It may seem counterintuitive, but the “closed” design of the drum brake is a major advantage under the harsh conditions trucks face. The system protects internal components from dust, mud, water, salt, and road debris. In a country with the geographical diversity found across the U.S., where a truck might cross desert highways and then face coastal salt spray on the same long haul, this protection is vital for brake longevity.

From a performance perspective, the story is more complex. Disc brakes, in fact, dissipate heat more efficiently and can reduce braking distance by up to 30% under certain conditions. However, drum brakes possess a larger friction area. This gives them excellent capacity to absorb heat generated during prolonged braking, such as long mountain descents.

Moreover, trucks are equipped with auxiliary braking systems, such as engine brakes (the famous “Scania engine brake” or “Jake Brake”), which reduce the load on service brakes. This creates a robust system that, although different, follows the same essential safety principles, as detailed in our comprehensive guide on brakes for performance and safety.

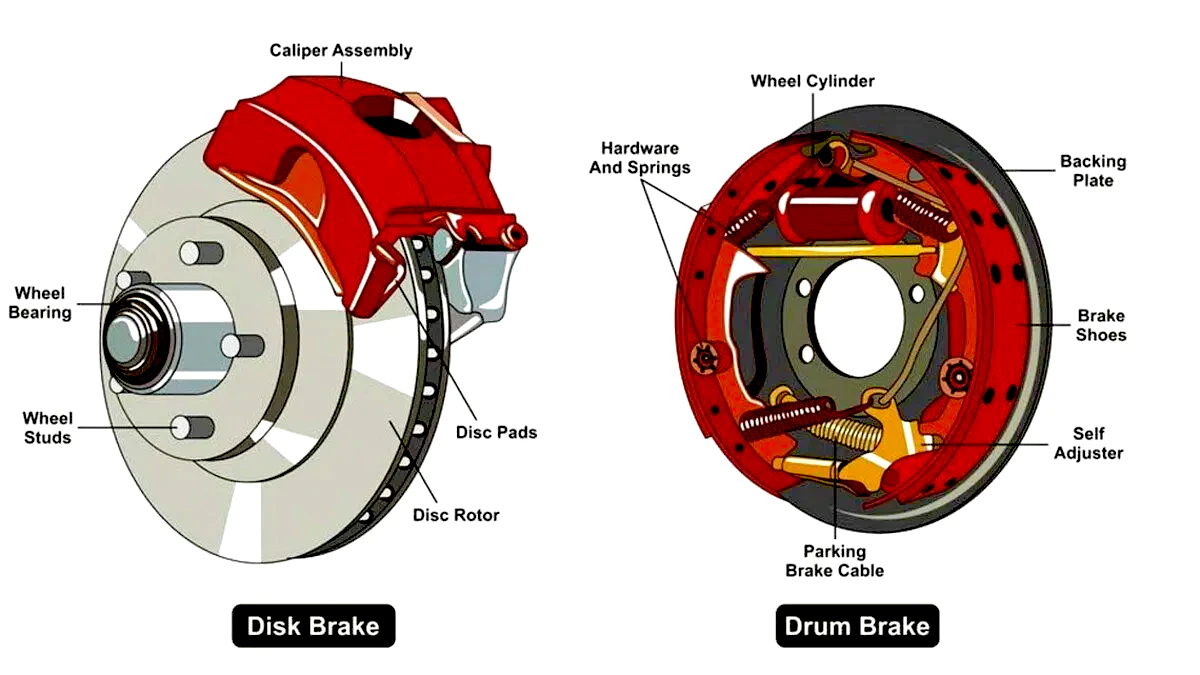

The Final Showdown: Drum vs. Disc – Who Prevails?

The truth is that there isn’t an absolute winner; there’s the right tool for each specific job. While disc brakes are superior in vehicles requiring frequent, heavy stopping (such as city buses and garbage trucks), drums retain their prominence on long, straight stretches of highways. The choice is an engineering and business decision that echoes in other industries where the trade-off between cost and benefit is critical, such as in the discussion about why laser headlights are so expensive.

To visualize this better, see this direct comparison:

| Aspect | Drum Brakes | Disc Brakes |

|---|---|---|

| Cost | Low initial and maintenance costs. Ideal for large fleets. | Higher initial and parts costs. |

| Durability | Excellent in dirty and corrosive environments due to the sealed design. | Exposed components, more susceptible to wear from contaminants. |

| Performance | Suitable for long hauls with less frequent braking. Good heat absorption capacity. | Better heat dissipation, shorter stopping distances, and more resistant to “fading” (efficiency loss due to heat). |

| Maintenance | More complex to disassemble, but with cheap parts and readily available labor. | Visual inspection and pad replacement easier, but specialized repairs are more expensive. |

| Best Application | Long-haul trucks, trailers, rear axles. | Buses, garbage trucks, delivery vehicles, steering axles. |

The current trend, however, is hybridization. Many new trucks leave the factory with front-axle disc brakes (where most braking force is applied) and rear-axle drums, aiming for the best of both worlds. After all, avoiding major issues is the goal, whether in the braking system or in engine carbonization, which requires diligent preventive care.

In the end, the continued presence of drum brakes on highway giants isn’t a sign of being technologically behind, but rather intelligent engineering focused on the real world, where durability and cost-benefit often outweigh the latest technological novelty. While the heavy-duty industry debates brakes, the light vehicle industry is already exploring the Chery gasoline engine with 48% efficiency, showing that evolution never stops, but always adapts to specific needs.