If you’ve ever opened the hood of an older car and seen a “web” of spark plug wires leading from a round cap, you’ve encountered a symbol of a bygone era: the distributor. There is a technical (and rather harsh) reason why the industry retired this component.

Distributor Vs. Coil Pack: What Changed In Ignition And Why It Matters

Every gasoline engine (and many flex-fuel engines when running on gasoline) relies on the same ritual: mixing air and fuel, compressing it, and igniting it at the exact right moment. The spark plug initiates combustion. And the ignition system is what “organizes” this spark.

In classic cars and many models up to the 1990s, the job was divided as follows:

- One coil generated high voltage.

- The distributor directed this energy to the correct cylinder.

- The rotor spun synchronized with the engine and “pointed” to each output terminal.

- The spark plug wires carried the high voltage to the spark plugs.

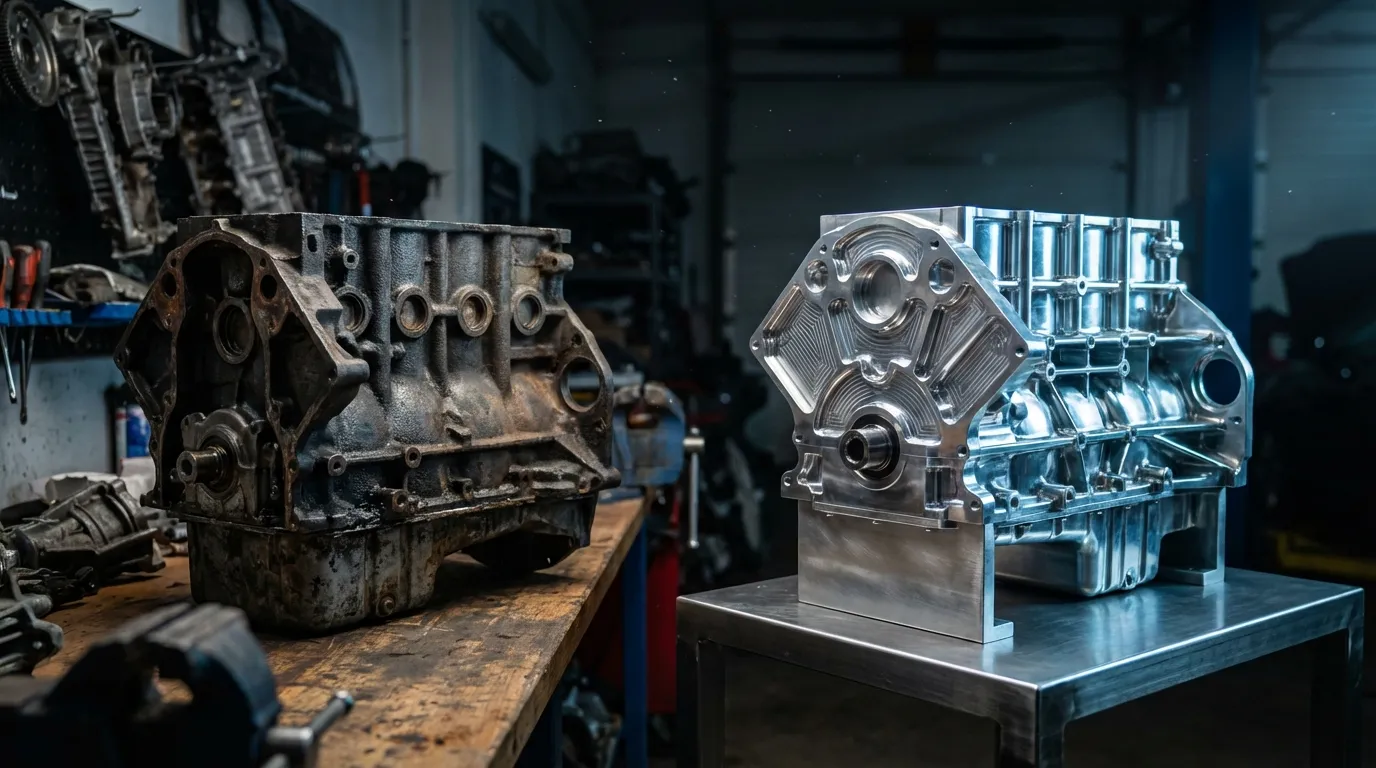

The problem is that this system works very well… until you demand too much from it. As RPMs rise, the engine needs faster and more precise sparks. In this scenario, the distributor begins to show its weaknesses: electrical losses, timing variation, mechanical wear, and sensitivity to moisture.

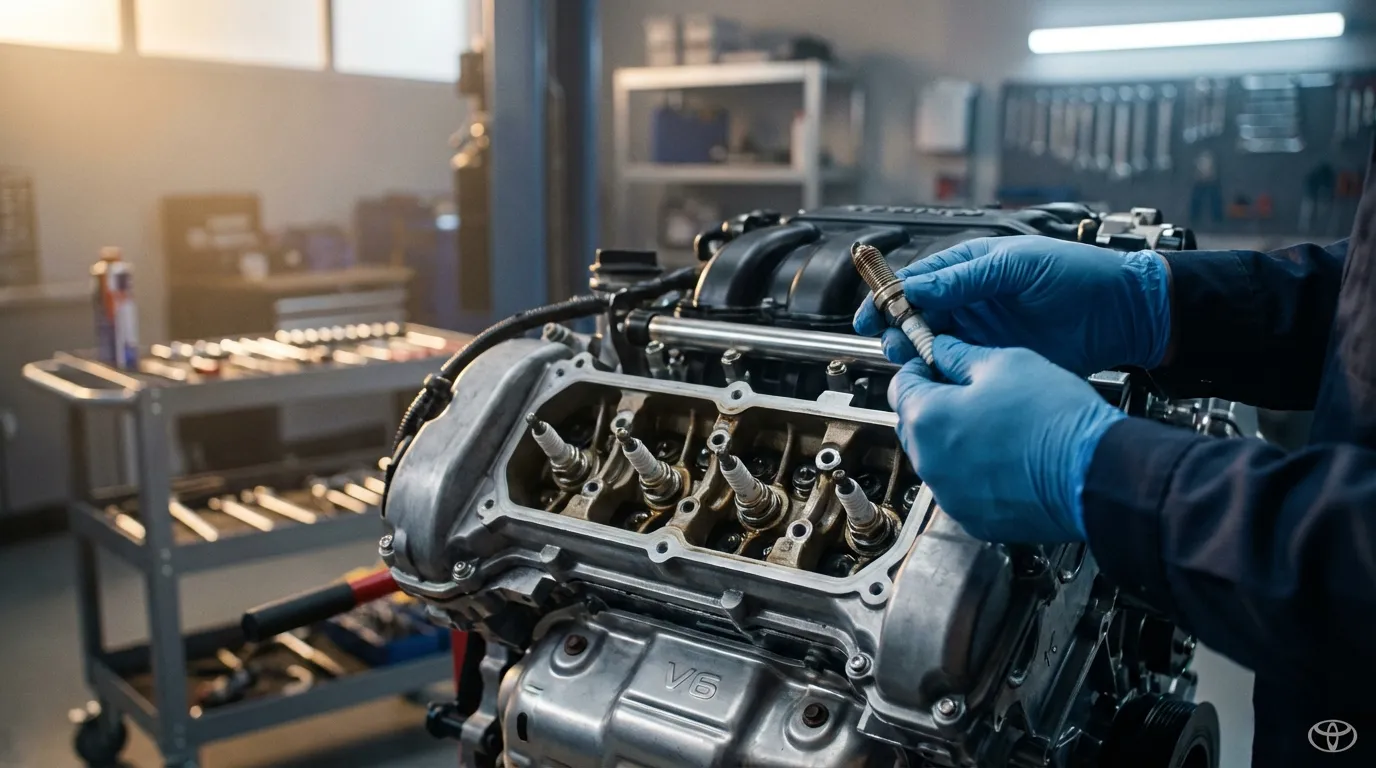

Modern systems (coil pack and especially coil-on-plug) have changed the game:

- Each cylinder receives a dedicated coil (or a pair of coils, depending on the design).

- The firing command becomes the task of the Engine Control Unit (ECU), utilizing sensors and maps.

- Long wires are eliminated (in coil-on-plug setups), reducing current leakage and interference.

In other words: ignition moved away from a mechanical piece “distributing” energy to an electronic delivery system that is stronger, cleaner, and delivered at the exact right instant.

Speaking of how small technical choices change the entire car, if you enjoy learning about this, it’s worth reading Hydraulic Lifters: Why Some Engines Use This Technology And How It Makes Your Car Quieter, because the logic is similar: less friction, less manual adjustment, more consistency.

The Real Reasons For The Switch: Efficiency, Emissions, Power, And Less Headaches

The question “Why did cars switch from distributors to coil packs?” has an answer mixing engineering and market pressure: the industry needed more efficient and reliable engines, complying with increasingly strict environmental laws, without turning maintenance into a weekly routine.

1) Ignition Precision at High RPM (The Distributor Runs Out of Breath)

The distributor relies on moving parts, clearances, and electrical contacts. At high RPMs:

- the rotor “sweeps” past the terminals too quickly;

- any clearance alters ignition timing;

- any electrical loss results in a misfire;

- repeatability drops.

With coil-on-plug ignition, the ECU controls the coil charging time (dwell time) and the firing instant based on sensors like RPM, phase, temperature, and load. The result: consistent spark even when the engine is running high and hot.

2) Stronger Spark and “Cleaner” Combustion

When the spark is stronger and more predictable, combustion tends to be more complete. This directly impacts:

- Fuel economy (less wasted fuel);

- Throttle response (fewer acceleration “hiccups”);

- Emissions (fewer unburned hydrocarbons in the exhaust);

- Cold starts (especially with modern injection strategies).

This point relates to a topic that almost no one pays attention to until it costs them money: using the correct, original spark plug. If you want to delve deeper into this, read Fake Ignition Coils: The Invisible Hit That Can Melt Your Engine And Drain Your Wallet.

3) Goodbye Long Wires: Less Current Leakage, Less Interference, Fewer Failures

In many older cars, spark plug wires were long, ran close to hot components, and suffered from drying out. Bad wires can cause:

- current leakage (spark “stolen” before reaching the plug);

- intermittent failures (the worst type of defect to diagnose);

- electromagnetic interference;

- internal cracks due to heat and vibration.

With coil-on-plug, the coil plugs directly into the spark plug. Less distance, less loss. It’s like removing extension cords and plugging directly into the wall outlet.

4) Less Mechanical Drag and Less “Old-Fashioned” Maintenance

The distributor is driven by a gear, usually connected to the camshaft. This adds a small mechanical drag and, more importantly, introduces wear-prone items: cap, rotor, contacts, advance mechanism, seals.

The coil pack eliminates this mechanical assembly and pushes the “intelligence” to the electronics. You trade a routine of adjustments and cleanings for a system that, in practice, usually runs for many years without intervention, as long as you keep the plugs and fuel in good order.

5) Emissions and Catalytic Converter: The Reason No One Sees, But Everyone Pays For

An ignition misfire sends unburned fuel into the exhaust. This overheats and damages the catalytic converter, which is one of the most expensive parts of the emissions system.

Therefore, modern cars monitor misfires and can even cut fuel injection to protect the catalytic converter. Coil-by-coil ignition allows for finer control and a lower chance of “silent” failure.

Want to avoid expensive garage traps and rushed diagnoses? Read Maintenance Mistakes That Are Making Your Mechanic Rich And Putting Your Safety At Risk.

Pros, Cons, and Signs of Coil Pack Issues (What Owners Need to Know)

Modern ignition isn’t “magic”; it’s better, but it has trade-offs. The difference is that instead of frequently replacing the cap and rotor, the cost might appear in other ways: coils and more electronic diagnostics.

Practical Advantages (In Real Life)

- More Usable Power and Response: Consistent spark improves combustion stability, especially during rapid acceleration.

- Better Economy: More complete combustion and less timing variation.

- More Reliable Starts: Especially in cold/humid conditions, as the distributor’s “Achilles’ heel” was exactly contamination and electrical leakage.

- Less Preventive Maintenance: Fewer moving parts, fewer adjustments.

- OBD Diagnosis: The car can register cylinder-specific faults (e.g., P0301, P0302, etc.), speeding up investigation.

“The distributor did everything at once: it generated the electrical path and depended on fine mechanics. Coil-on-plug separates tasks and gives the ECU control over timing, force, and repetition.”

Disadvantages and Pitfalls

- Cost Per Unit: There are cheap coils and very expensive coils, depending on the engine.

- Diagnosis Can Be Confusing: An ignition failure isn’t always the coil; it could be the plug, injector, vacuum leak, compression, or a sensor.

- Replacement as a Set: In some cases, it makes sense to replace coils along with long-life spark plugs, especially if access is difficult.

By the way, if you’re unsure about spark plug technologies and replacement intervals, this guide fits perfectly here: Iridium or Platinum In Your Car? Discover Which Spark Plug Is Right For You.

Classic Symptoms of a Failing Coil (or Ignition System)

- Stumbling under load (uphills, A/C on, passing maneuvers).

- Rough idle and noticeable vibration.

- Check Engine Light On and misfire codes (P0300 to P030x).

- Strong fuel smell in the exhaust (unburned fuel).

- Power loss while consumption simultaneously increases.

Does the Distributor Still Exist? Yes, But It’s Now the Exception

In modern passenger cars, it is extremely rare. The distributor remains more common in:

- Classic and collectible cars;

- Older projects in specific markets;

- Special application engines (depending on the country and regulations).

In practice, the combination of Electronic Fuel Injection + ECU + Coil Pack/Coil-On-Plug won out because it delivers something the distributor cannot maintain for long: repeatable precision. And in the real world, repeatable precision means less consumption, lower emissions, more performance, and fewer cold start scares on a damp morning.

| Criterion | Distributor | Coil Pack / Coil-On-Plug |

|---|---|---|

| High RPM Precision | Limited by wear and mechanics | High, controlled by the ECU |

| Maintenance | More frequent (cap/rotor/wires) | Less frequent, though parts can be expensive |

| Moisture Resistance | Sensitive (can fail when wet) | More robust |

| Emissions & Efficiency | Less fine control | Greater fine control and more stable combustion |

| Diagnosis | More “manual” | OBD helps, but requires reading and method |

If your car still uses a distributor, it doesn’t mean it’s “bad”—it means it belongs to a generation where mechanics handled tasks now managed by electronics. But if you want to understand why current engines seem so “perfect” in operation, even with low displacement, turbocharging, and strict emission targets, the answer starts here: the spark stopped being a well-aimed guess and became a calculated shot.