See the real reason why automakers abandoned iron for aluminum. Understand how this change affects durability, weight, and the future of automotive power.

Have you ever wondered why old engines seemed to last forever, tolerating mechanical abuses that would send a modern car straight to the junkyard? The answer lies deep within the engine bay, in the backbone that holds all the horsepower: the engine block. For decades, cast iron was the undisputed king, a material synonymous with robustness and brute strength. However, a silent but aggressive revolution transformed the industry, replacing heavy metal with lightweight and technologically advanced aluminum. But was this switch just to save fuel, or is there a hidden engineering agenda? The transition was not without catastrophic failures and technical challenges, and understanding this change is crucial to know what truly beats beneath your vehicle’s hood.

The Obsession with Weight and the European Influence

The common narrative states that aluminum is a recent innovation, a modern response to the climate crisis. That is a historical mistake. The automotive industry has flirted with aluminum for much longer than most think. As early as the 1960s, iconic brands like Chevrolet were at the forefront with the legendary CHEVROLET RPO ZL1, a 427 engine with an aluminum alloy block that became the “holy grail” for collectors and performance enthusiasts. Other brands, like Oldsmobile, Chrysler, and Plymouth, also experimented with the material at the same time.

The original push, surprisingly, came from a need for competitiveness in the compact market and from European engineering influence, which had already made significant advances in aluminum metallurgy. Physics here is relentless: iron is nearly three times denser than pure aluminum. In a market where every kilogram counts, this difference is monumental.

Reducing weight not only improves fuel consumption; it transforms driving dynamics. Less weight on the front axle means more precise cornering entry and less suspension and brake wear.

Today, the motivation has evolved from “performance in compacts” to a strict regulatory necessity. With the Environmental Protection Agency (EPA) and global agencies tightening standards on CO2 emissions, automakers had no choice. To reduce consumption without sacrificing power — something vital in cars like the AUDI RS6 AVANT PERFORMANCE 2026, the last gasp of V8s — the diet had to be extreme. Aluminum allowed larger engines to continue existing in lighter bodies, maintaining the relevance of combustion engines for a few more years.

Below, see a direct comparison of the physical properties that drove this decision:

| Characteristic | Cast Iron | Aluminum Alloy |

|---|---|---|

| Density | High (Heavy) | Low (Light, approx. 1/3 of iron) |

| Heat Transfer | Slow | Excellent (Dissipates heat quickly) |

| Production Cost | Generally lower | Higher (raw material and refining) |

| Vibration Absorption | High (Quiet) | Low (Requires more insulation) |

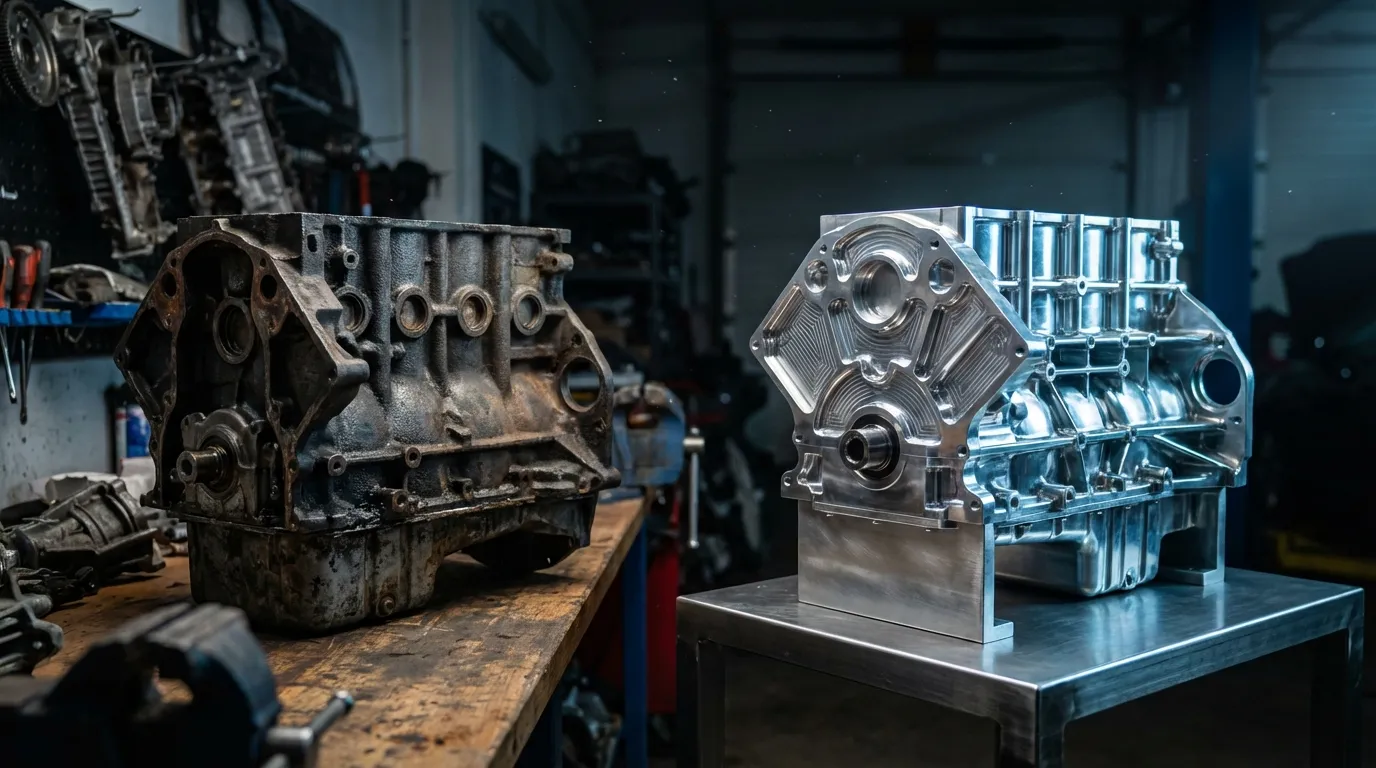

Cast Iron Resists: Durability and Acoustic Properties

Don’t be misled into thinking cast iron is obsolete technology ready for museums. It remains the preferred choice for applications where extreme durability outweighs weight savings, such as in heavy-duty Ram and Dodge trucks, and in insane build projects. There is a deep technical reason for this, far beyond nostalgia.

The density of iron, which is its “enemy” on the scale, is its greatest ally in durability and comfort. Cast iron is exceptionally good at muffling mechanical noises and vibrations (NVH – Noise, Vibration, Harshness). Sound waves have difficulty traveling through the dense structure of graphite compacted in iron, making the engine naturally quieter. In contrast, aluminum blocks tend to “resonate” more, requiring acoustic covers and complex mounting engineering to prevent transmitting roughness into the cabin.

Furthermore, in scenarios of catastrophic failure or overheating, iron is much more forgiving. Pushing an iron engine beyond its limits can cause thermal distortions that, in an aluminum block, would result in irreversible warping of the cylinder head or the block itself. That’s why, in high-performance internal components discussions, material choice is critical, as seen in the detailed analysis of Aluminum Pistons vs Cast Iron: Which Dominates in Supercars? When subjected to extreme thermal stress without proper cooling, aluminum can fail dramatically, requiring costly repairs or total engine replacement.

The Hybrid Solution and Engineering Challenges

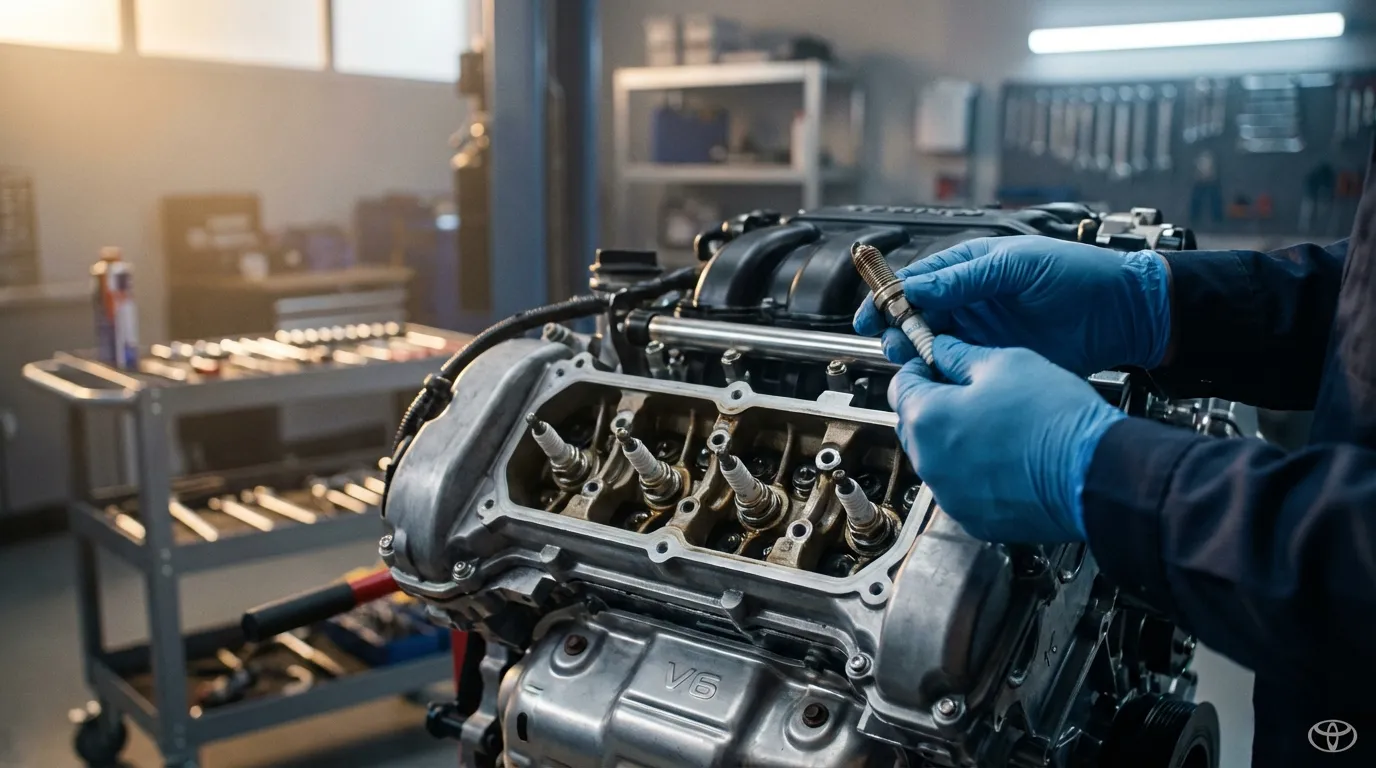

To try to get the best of both worlds, modern engineers have developed hybrid solutions. The vast majority of current aluminum blocks are not 100% aluminum where it truly matters: in the cylinders. Direct contact of piston rings with soft aluminum would cause unacceptable premature wear. The solution? Cast iron cylinder sleeves inserted into the aluminum block during casting or pressed in afterwards.

This “mixed architecture” combines the structural lightness of aluminum with the wear resistance of iron. However, it creates its own challenges. Iron and aluminum have different coefficients of thermal expansion — that is, they expand and contract at different rates when heated. This requires precise engineering of head gasket joints and machining tolerances. When something goes wrong in this complex system, such as low-quality ignition components that alter combustion chamber temperature, the result can be disastrous. A clear example is the hidden danger of fake spark plugs, an invisible hit that can melt your engine, especially sensitive in lightweight alloy blocks.

Evolution doesn’t stop. Modern supercars are pushing metallurgy to its limits. Vehicles like the LAMBORGHINI TEMERARIO use special aluminum alloys and high-tech casting processes to withstand insane turbo pressures that previously would require the weight of iron.

On the other hand, this pursuit of efficiency also explains the trend of downsizing. Why Did Turbo 4-Cylinder Engines Replace V6s and V8s? Unpacking Fuel Economy and Reliability Myths Partly because a smaller aluminum block drastically reduces the overall vehicle weight, creating a virtuous cycle of efficiency that cast iron simply can’t keep up with in the modern era.

The industry continues to test limits. Experiments with oil-less engines, piston ring-less designs, and microscopic clearances have been attempted, but machining complexity hindered mass production. For now, aluminum dominates passenger cars, but cast iron remains the guardian of brute strength, reminding us of an era where weight was a synonym for quality.